What is Steel Structure Packing Requirments and Packing Way?

Firstly, Steel structrue packing basic requirements

1. According to the characteristics of sea and inland transportation way, such as loading and unloading times, transportation distance and long period of transportation, Reasonable design, rational use of materials and equipment should be considerated. To ensure the convenience and safety of loading and unloading, stacking and storage of materials during the whole transportation process at home and abroad.

2. Packaging design should have a certain stacking capacity. For the goods with height of more than 2 meters, stacking of three sets similar goods. For the goods with a height of less than 2 meters, stacking four or six identical goods.

3. The design of lifting position: All lifting pisiton are designed based on the length, weight and gravity of the goods, especially the larger packaging. So that the packaging can be balanced in the lifting process.

4. Center of gravity and mark: Packing place should be marked . Each piece of goods must have two marks hanging on both sides at the same time. The contents of the marks are identical, and the marks must be clearly visible. The marking nameplate shall be fixed on the packing rack with rivets.

5, The width and height of single package should be below 1.4 meters . the width and height of group packages should not exceed 2.8 meters. If the width or height of a single component exceeds 2.8 meters, the design department should consider interrupting the components. Packaging rack must be soldered firmly. it must be coated with rust-proof primer to avoid rusting and corrosive.

Secondly, Steel structure and accessory packing way

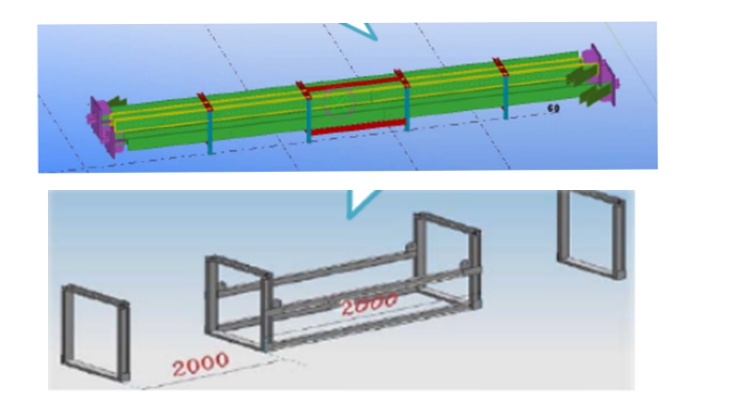

1,Bundling package. Medium-size steel component are usually bundled, such as steel beams, steel columns, supports, etc.

A Length of less than 5 meters should be bundled two line, the middle distance is 2 meters, the length is more than 5 meters

B,The Cushion Components are needed between two parts , such as pearl cotton. To ensure that the components can not slide each other.

C If the package is fixed by screw, it is necessary to spot weld nuts to prevent transportation from falling off.

DThe lifting lugs shall be added to the package to facilitate loading, unloading and transportation. The lifting lugs need to be soldered firmly.

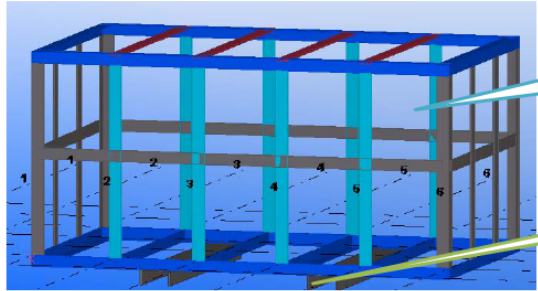

2. Frame package

Small components, f welded brackets, etc. shall be packaged in frame . The frame made by channel steel,or angle steel as materials. Frame mesh must ensure that the internal components will not be present, the components installed in the framework need to be separated by pearl cotton, in order to avoid damageduring transportation, the bottom of the frame must be left with shovel holes to ensure loading and unloading.

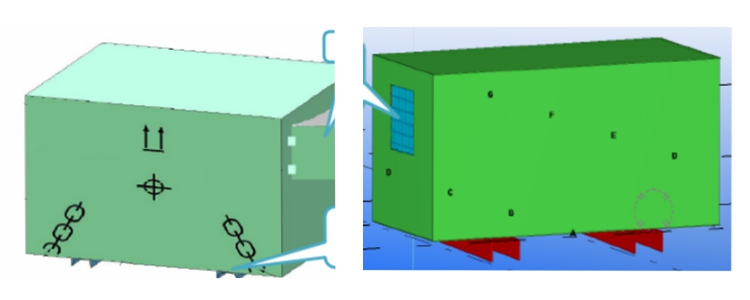

3. Iron boxes package, bolts, connection boards and other easily spare parts need to be packaged in iron boxes. The box are made of angle steel, channel steel and steel plate.Customs observation window should be used in the middle of the frame. Drainage holes should be left at the bottom of the frame, The shovel holes should be left at the bottom of the iron box to ensure loading and unloading.

4. Bare assembly, Generally used for large structural parts, bare components should be placed on the chassis, the design should conform to the balanced force, stable and reliable, easy to load and unload.

5, Other package

A,Barrel package, used for paint, chemical materials, etc.

B,Coiling package , iused for the packaging of wire, cable, wire rope and other goods.

C,Pallets pacage, used for the goods packed in combination

6, Wall and roof panel package

-

BR PREFAB went to Japan to exchange construction technology

BR PREFAB went to Japan to exchange construction technologyAs member of Chinese Steel Structure Association, BR PREFAB was invited to Janpan to exchange construction technology

BR PREFAB gained a deeper understanding of Japan's advanced technology , particularly in seismic performance, environmentally friendly materials, and intelligent construction. Japanese management system and construction mode also ...Do you like ?0

Read more -

BR PREFAB attend Worldbex in Philippines

BR PREFAB attend Worldbex in PhilippinesWORLDBEX stands for the Philippine's building and construction exposition. it is a pillar of the country’s construction and design industry for its premiere and world-class trade presentations. Gathering the finest local and international companies that cater to a wide variety of construction and design needs, WORLDBEX is supported and acknowledged by distinguished sectors and or...

Do you like ?0

Read more -

BR PREFAB attend The Big5 construct exhibition

BR PREFAB attend The Big5 construct exhibitionLaunched in 2010 with a mission to fully equip Saudi Arabia’s construction sector amidst its huge development plans, The Big 5 Saudi is the Kingdom's leading construction event. The Big 5 Saudi continues to serve as a true testament to the country’s growing attractiveness in the global construction arena, bringing together industry players in support of the Kingdom’s ambit...

Do you like ?0

Read more -

Prefabricated Houses Matchmaking Meeting Of Overseas Projects-BR PREFAB

Prefabricated Houses Matchmaking Meeting Of Overseas Projects-BR PREFABPrefabricated Houses are in big demand of developed countres. From May 15th to 17th, 2019, the 11th China (Guangzhou) International Integrated Housing Industry Expo was held at the Poly World Trade Expo Expo. BR PREFAB was invited as a leader in China's green assembly building. BR PREF...

Do you like ?0

Read more -

Prefab Houses Factory Completed The Audit of ISO9001

Prefab Houses Factory Completed The Audit of ISO9001The prefab houses factory of our group successfully held the audit meeting of ISO9001 quality management system in our manufactured homes factory On June 18, 2019, . The meeting was hosted by Mr. Chen, a consultant from Guangzhou Consulting co.,. All the senior...

Do you like ?0

Read more -

Prefab Steel Structure Factory attended 124th Canton fair

Prefab Steel Structure Factory attended 124th Canton fairPrefab Steel Structure Factory BR PREFAB focus on labor camp, container house, steel structure, light steel villa, portable toilet and security room for more than 10 years. The booth stand are located in the brand area, That is a place to meet...

Do you like ?0

Read more